Internal Application / Workshop + Solution / Product Designer

Assisting a WORKSHOP to figure out Pain Points + Possible Solutions

for a Top US Energy company

Scroll ↓

The Setup

Business

Transmission business squad at the energy company

Challenge

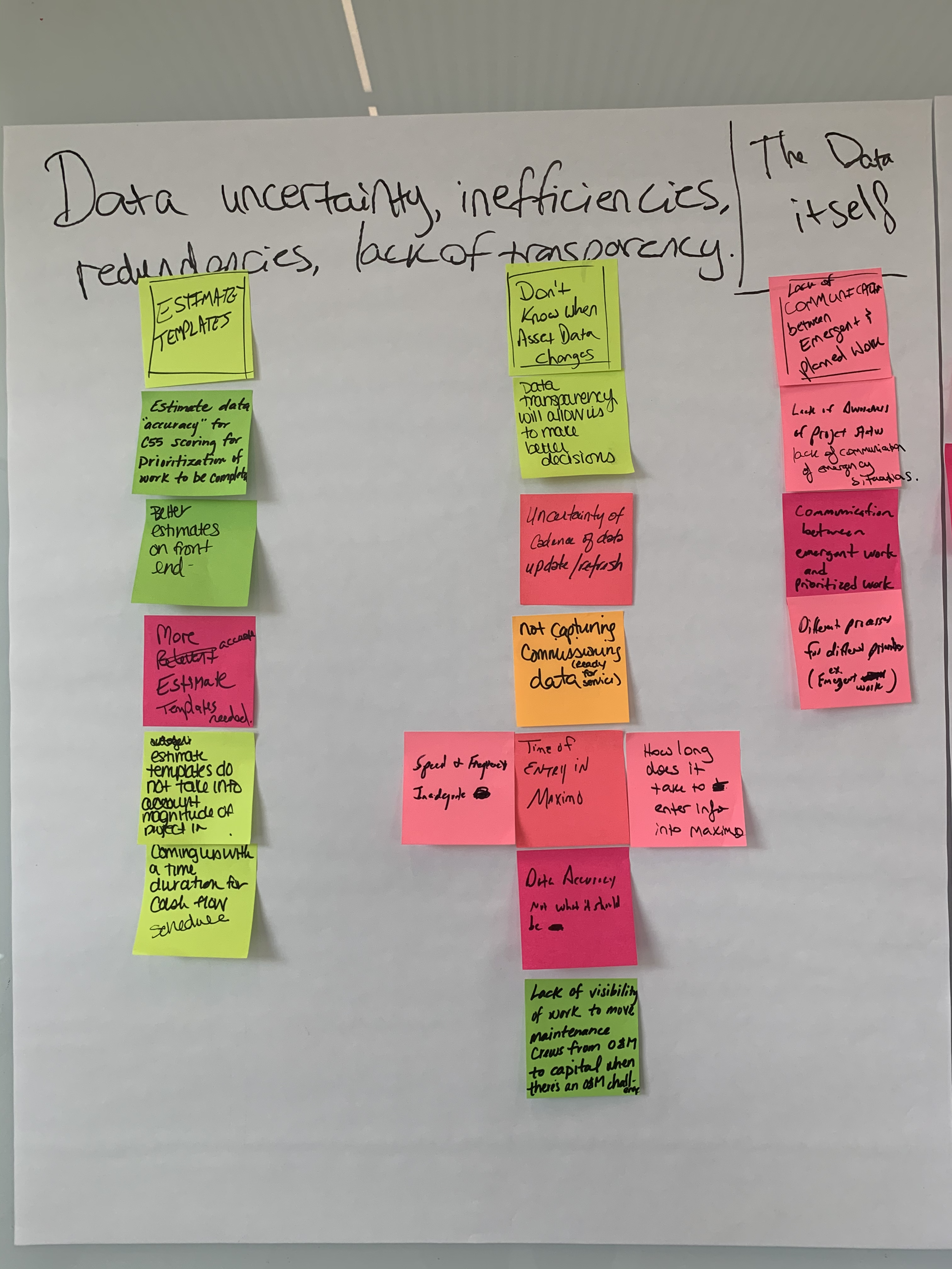

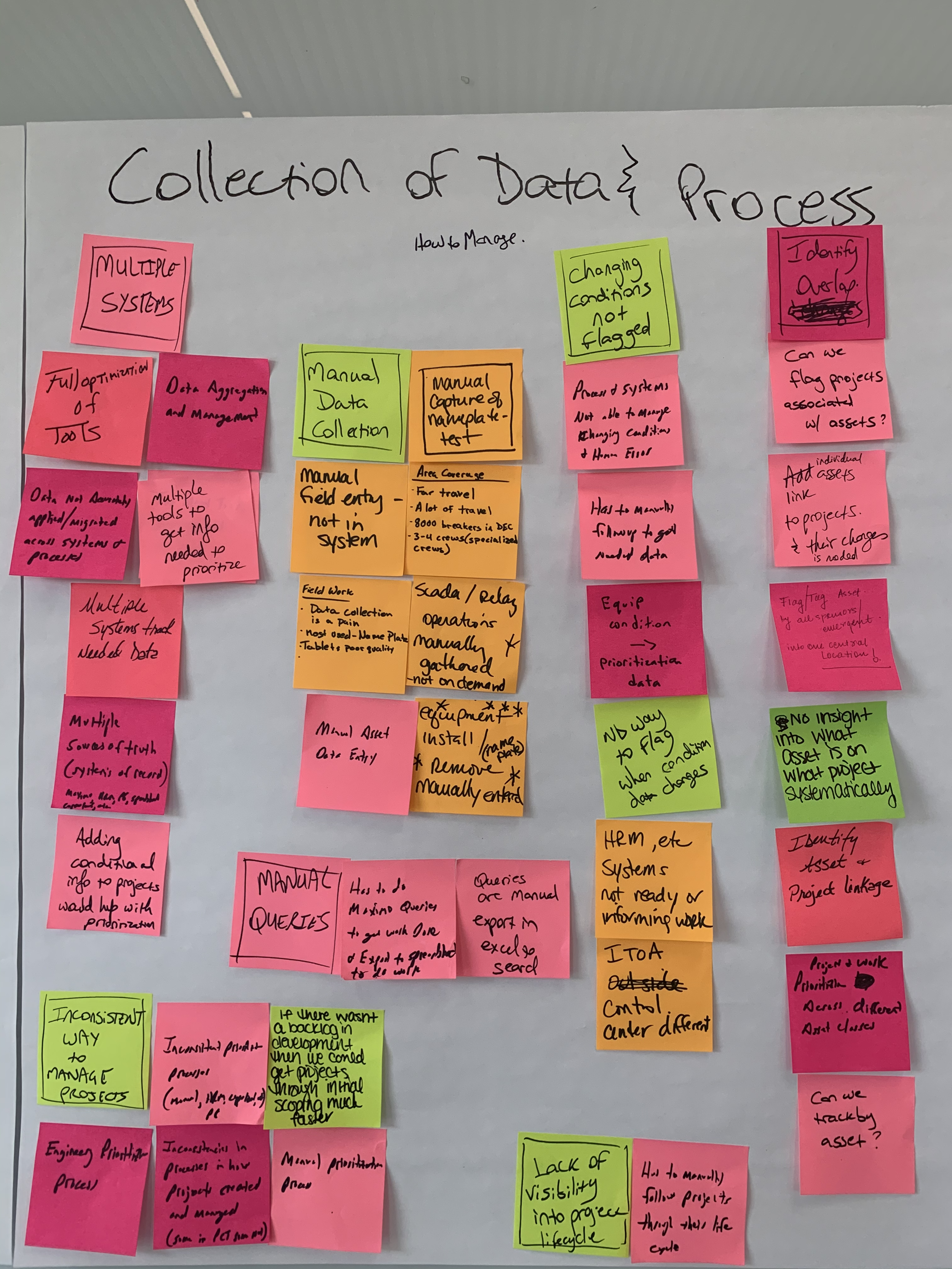

The challenge was to work hand in hand with our stakeholders to learn their current workflow, gain a list of pain points within the business squad, and evaluate those to decipher what the best MVP would be to start increases presence and experience for Transmission

My Role

Assist in creating visuals (mid-to-high fidelity) of a possible solution to the business units pain points

Project Time

Six months consisting of an incubator workshop and refinery phase to work on probable solution

Transmission Team

-

Portfolio Owner

Dana Adams

-

Construction & Maintenance

Christy Guenther

-

Asset Management

Tab Jordan

-

Long Term Planning

Cassandra Brooks

-

IT

Delsi Love

-

Change Management

Erika Sanchez

-

Designer

Jorey Jones

Week 1 of Workshop : The Current State

-

Validate Presented Workflows

Understand the backstory

-

Define Opportunities

Align scope of opportunities and potential

-

Define Group Impact

Define problem statement to ground ideation of future vision

-

Discovering Validation

Linking together users, problems, and opportunities to solve them

Workshop Exercises

-

Crazy Eight’s

Rapid ideation of concepts that may inform a future state

-

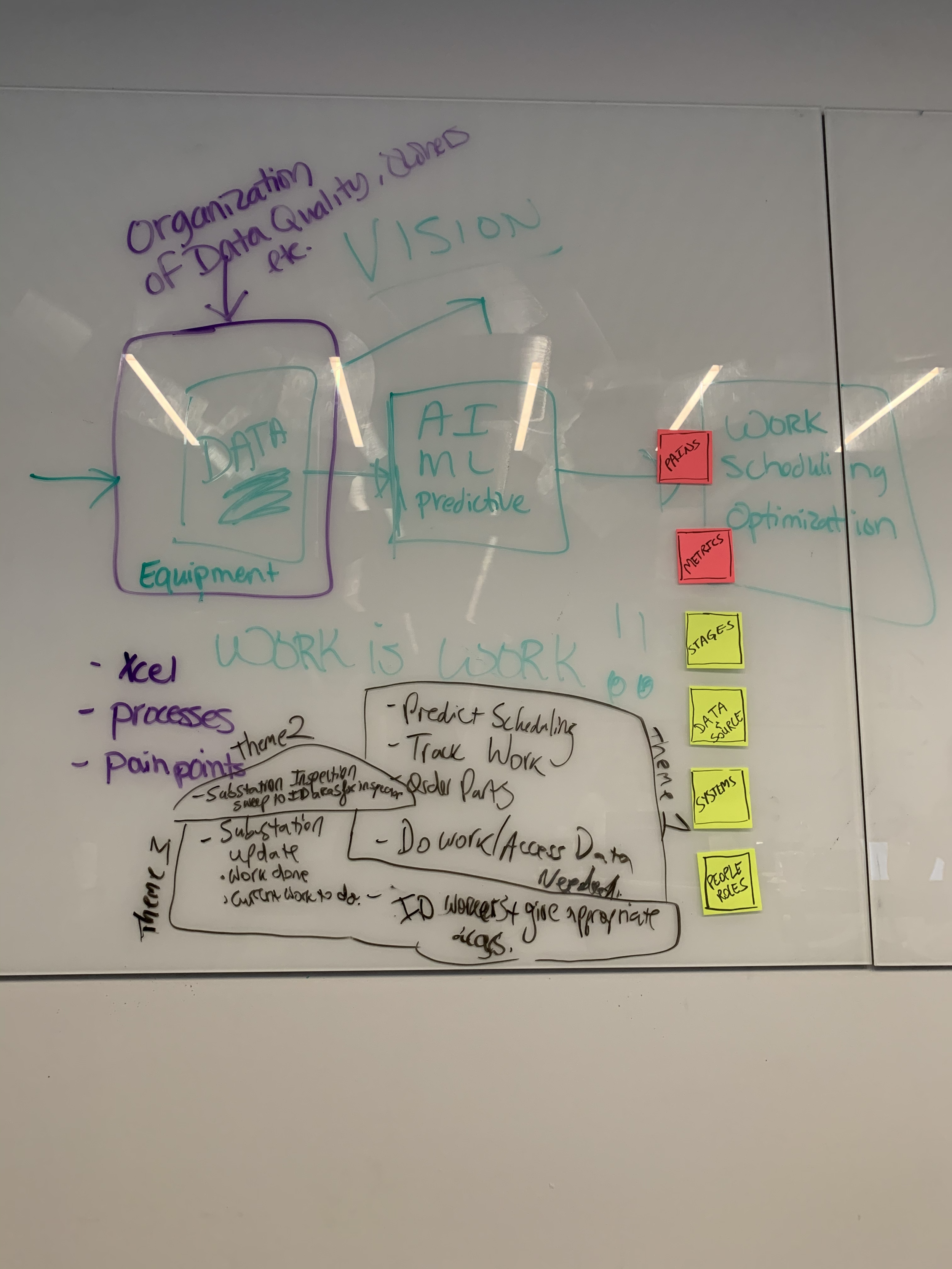

Future State Workflow

Reimagine the future state that reduces identified pains

-

Vision Board Poster

Visual representation of our opportunity

-

Foundation

Updated stakeholder map to identify the user

Opportunities

-

Work Prioritization

Data aggregation and sharing

Actionable data relevant to work

-

Data Collection

Work prioritization

Cognizant sub-station

Leverage existing data used by other groups

-

Capital Asset

Equipment tracking

Feeding work management systems with equipment change info.

Risks

-

Work Prioritization

Bad data in / bad data out

Weak in execution

Not meeting rate expectations

-

Data Collection

Impact is high

Dependent on data collection

-

Capital Asset

Bad data in / bad data out

Compliance

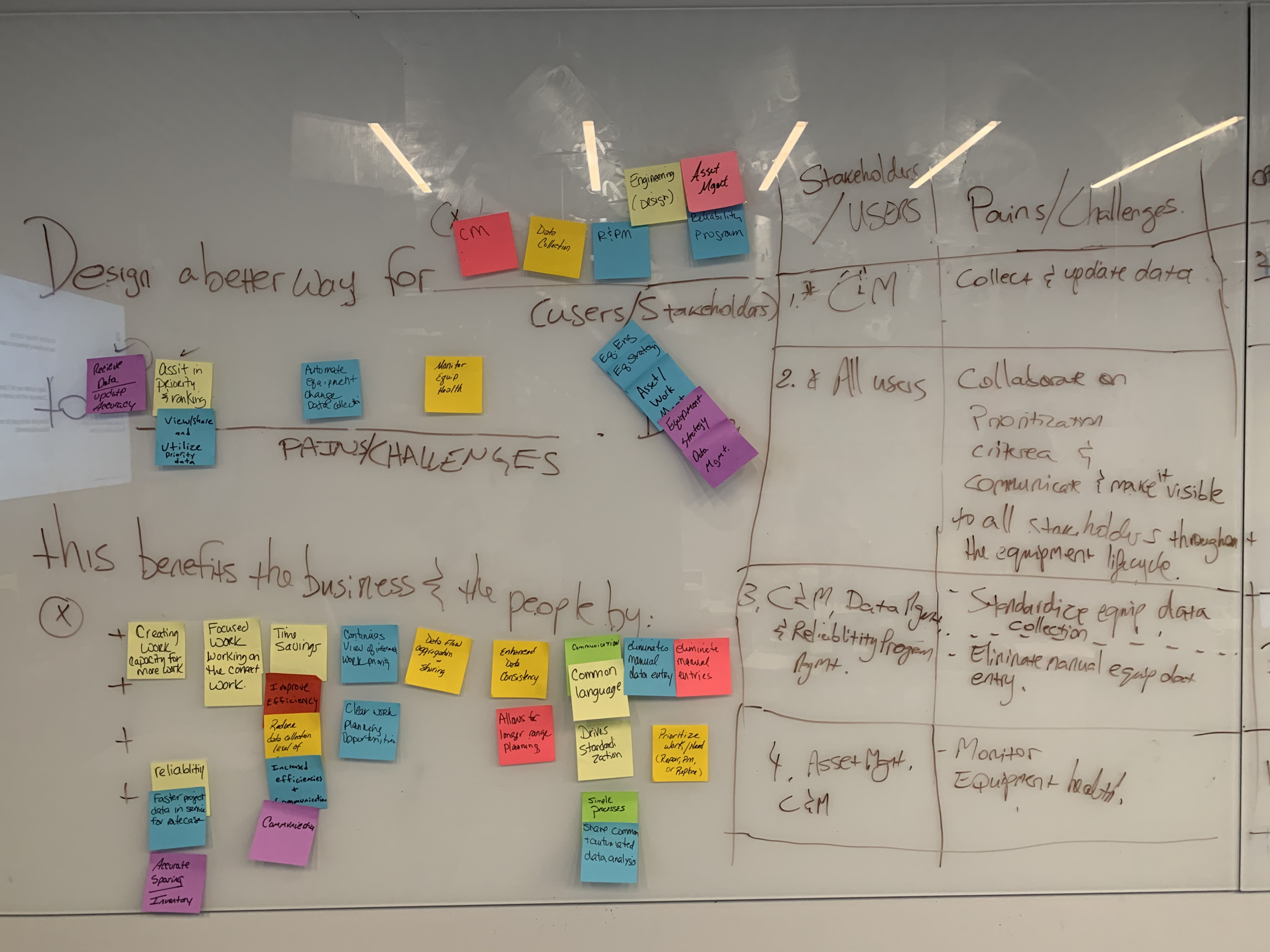

Opportunity Statements

Design a way for C&M, MANAGEMENT, AND RELIABILITY PROGRAM MANAGEMENT

to STANDARDIZE DATA COLLECTION, UPDATE THE DATA, AND ELIMINATE MANUAL EQUIPMENT DATA ENTRY. So that all work can be PRIORITIZED, ALLOWING FOR CROSS-DEPARTMENT ALIGNMENT, VISIBILITY, AND COMMUNICATION OF PRIORITIZATION CRITERIA throughout the equipment lifecycle.

Design a way for SPONSORS to LEVERAGE ASSET DATA TO PREDICT LONG TERM ASSET STRATEGY AND SYSTEM PLANNING REQUIREMENTS to OPTIMIZE RESOURCE AND OUTGOING PLANNING TO EXECUTE HIGHEST PRIORITY WORK.

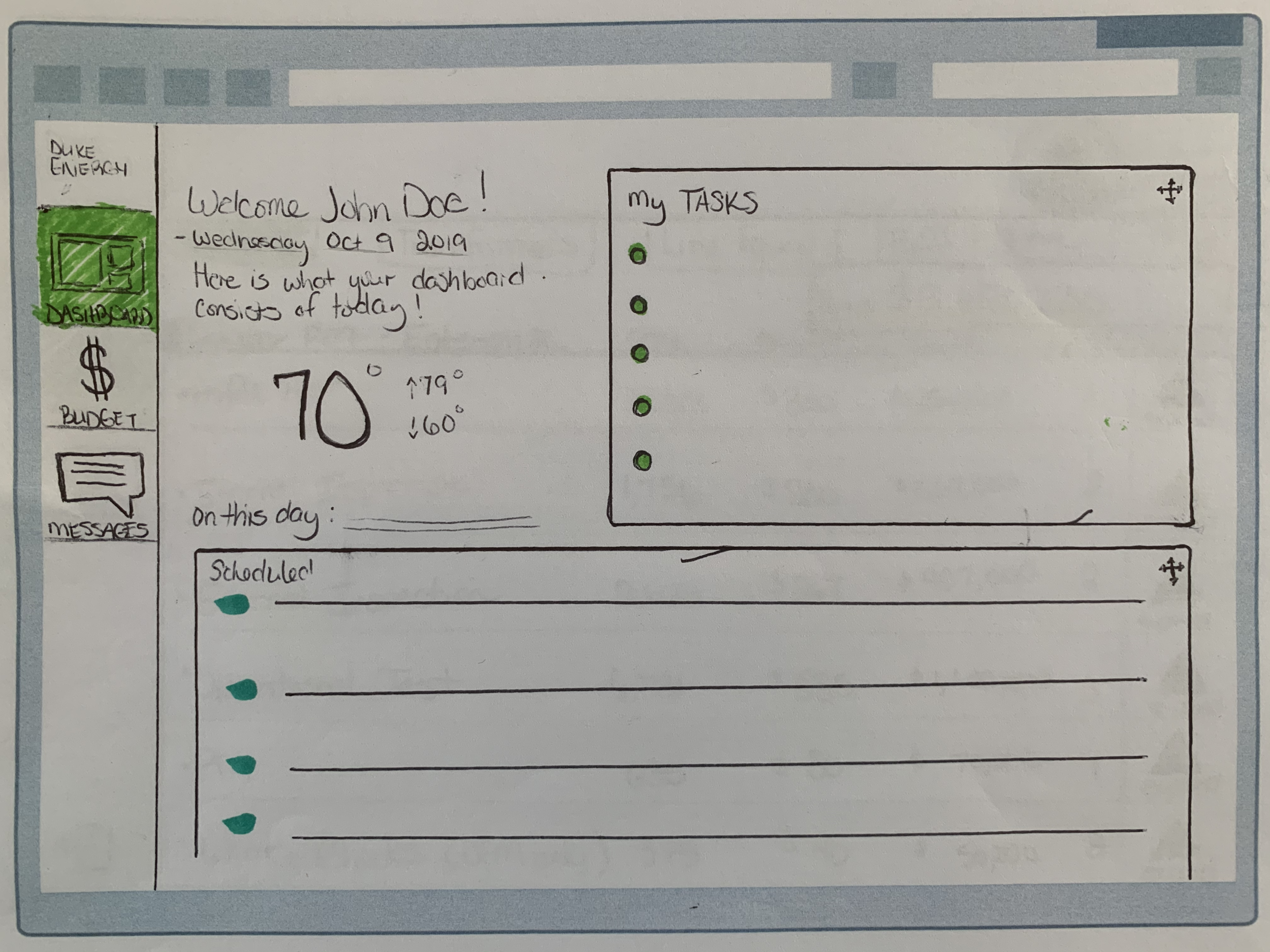

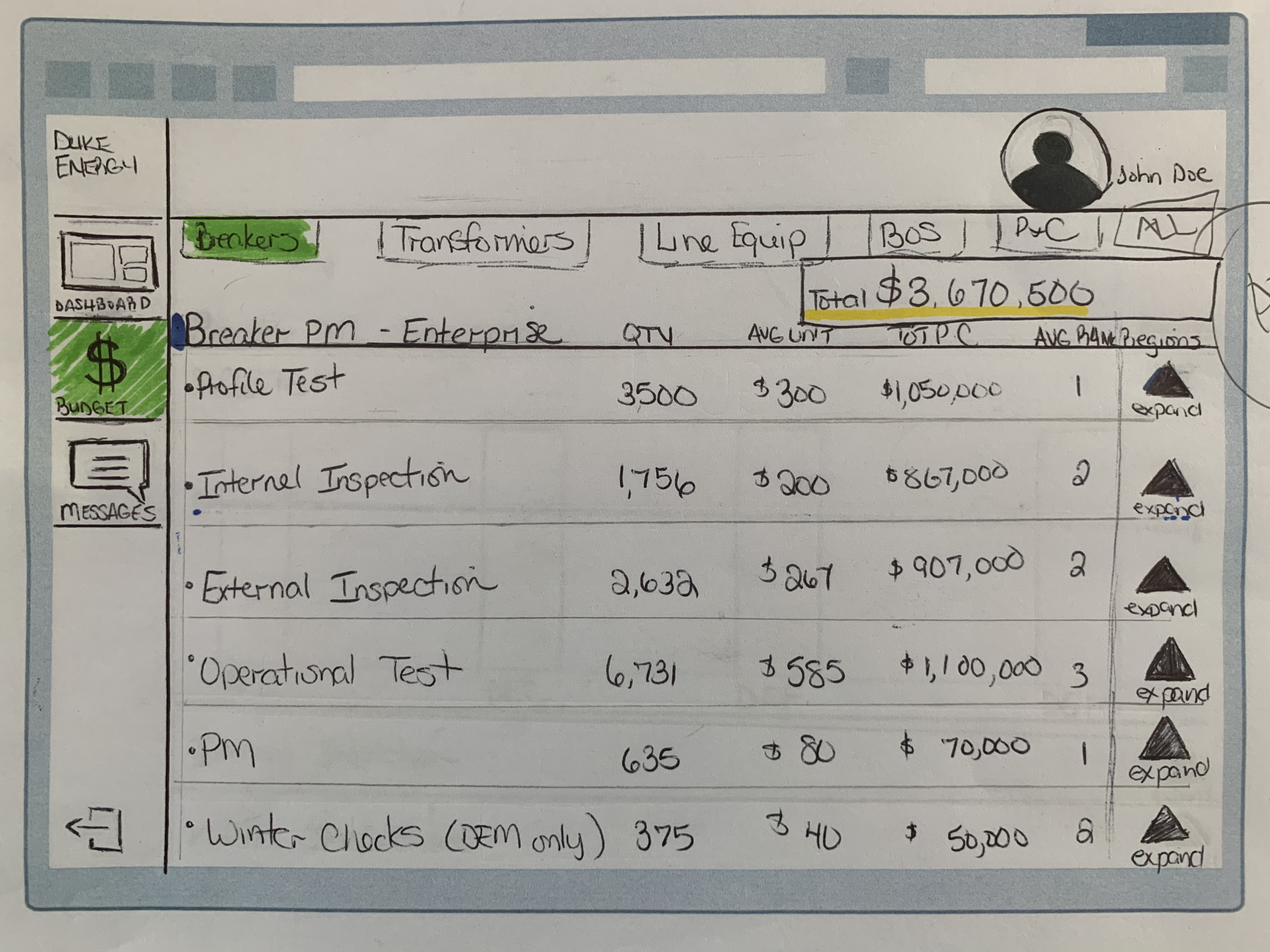

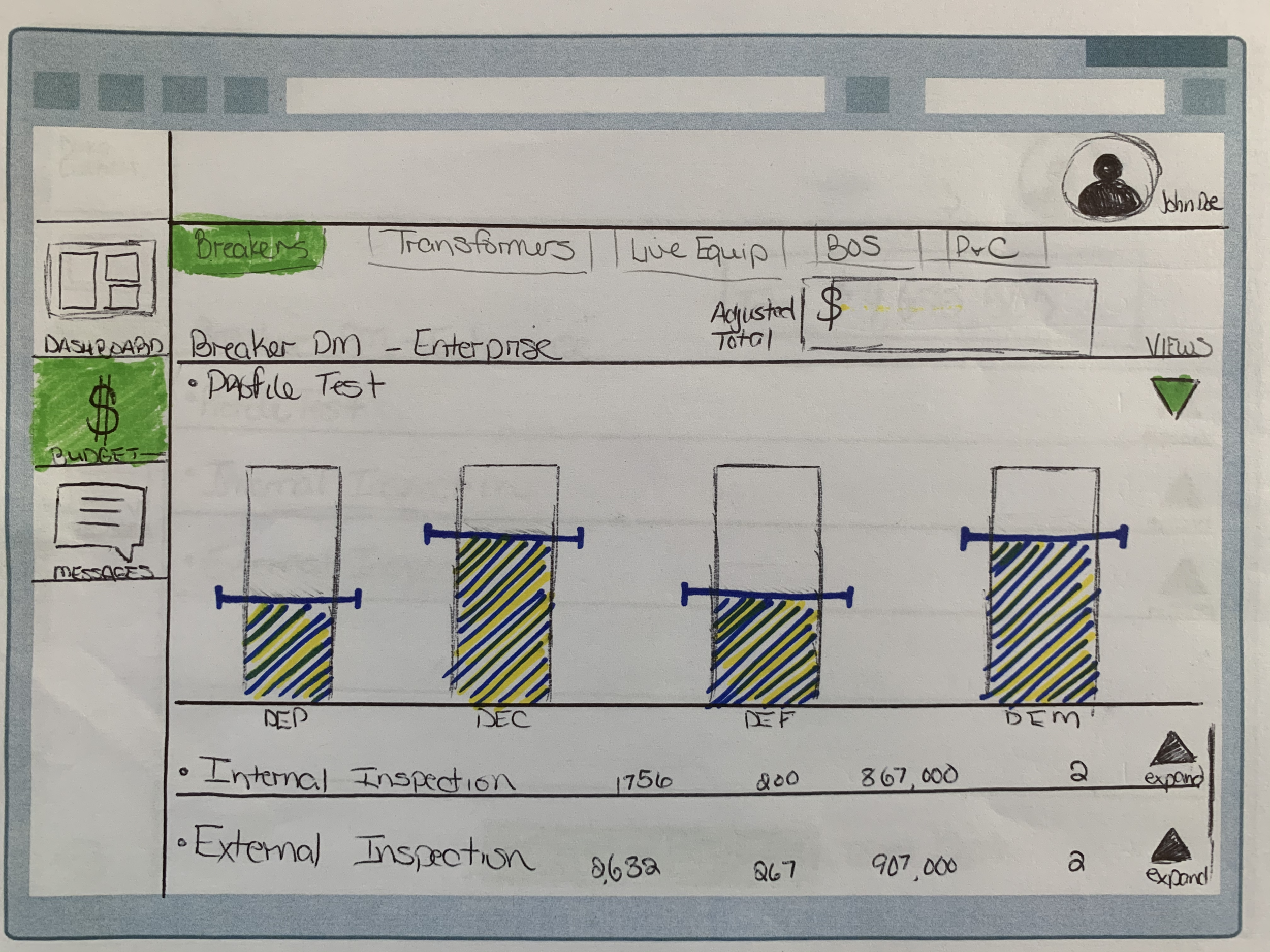

My Role up to this point

My role was to help understand the reasoning behind all exercises to come towards a sole problem to solve. We didnt want them to just create a solution in our first iteration (which was hard when you are working with stakeholders who are having the problems with their current workflow) but critically think how this could expand and effect the Transmission team. I created the Vision Board Poster sketches, which ended up being the focal point as I used this sketch as my description of what I felt the problem that we occuring.

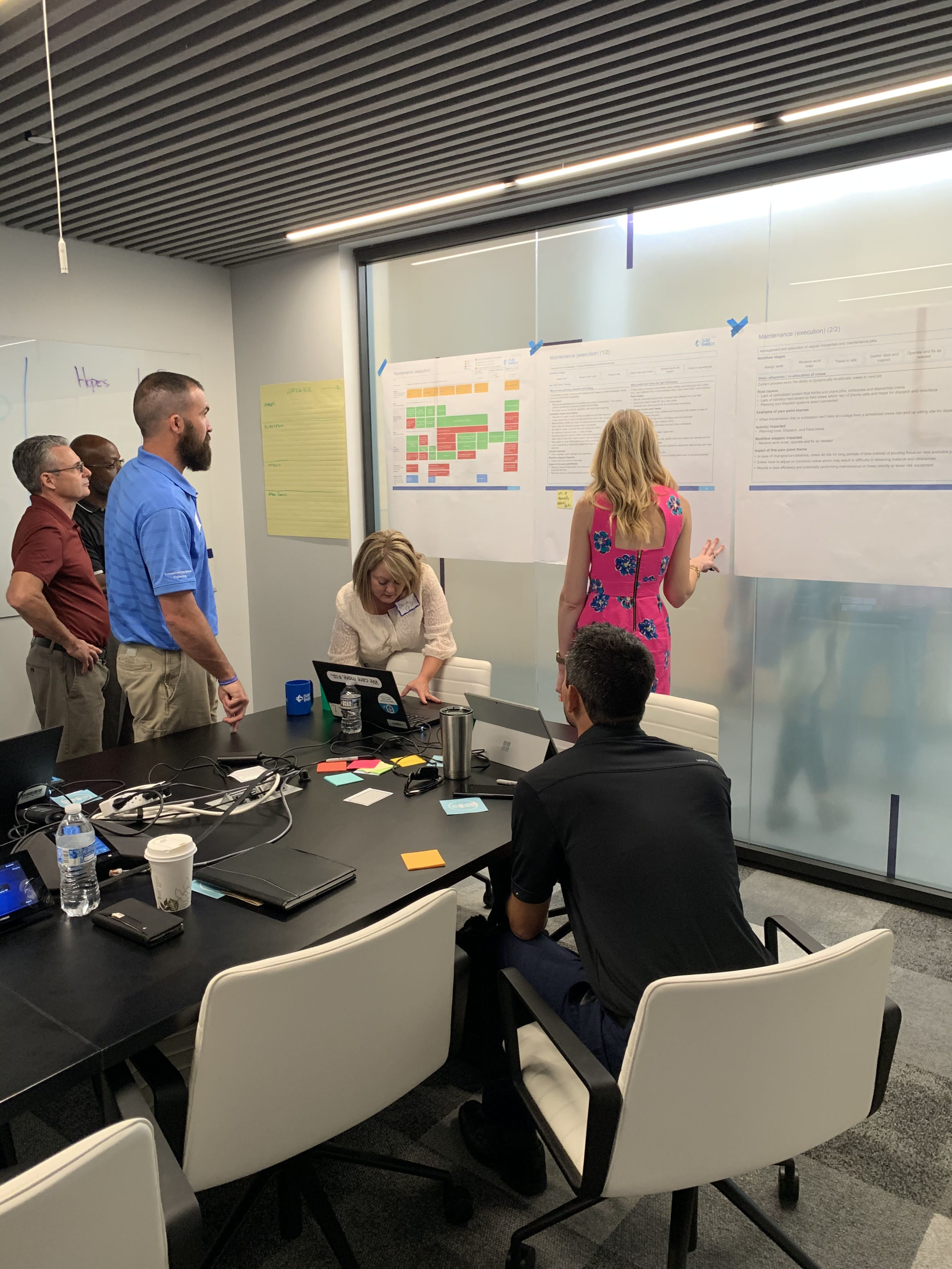

Week 2 of Workshop : Prioritizing the MVP

-

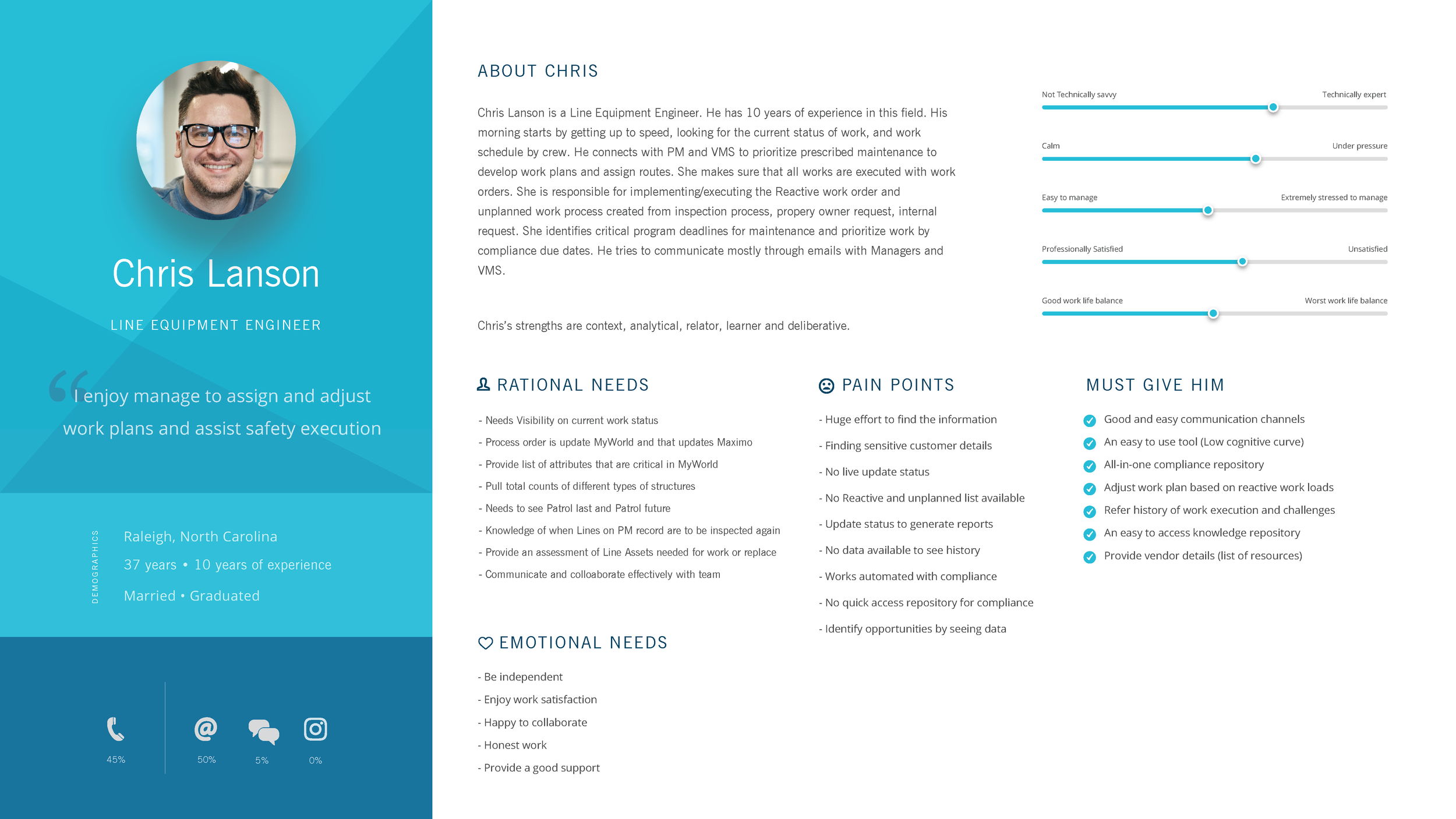

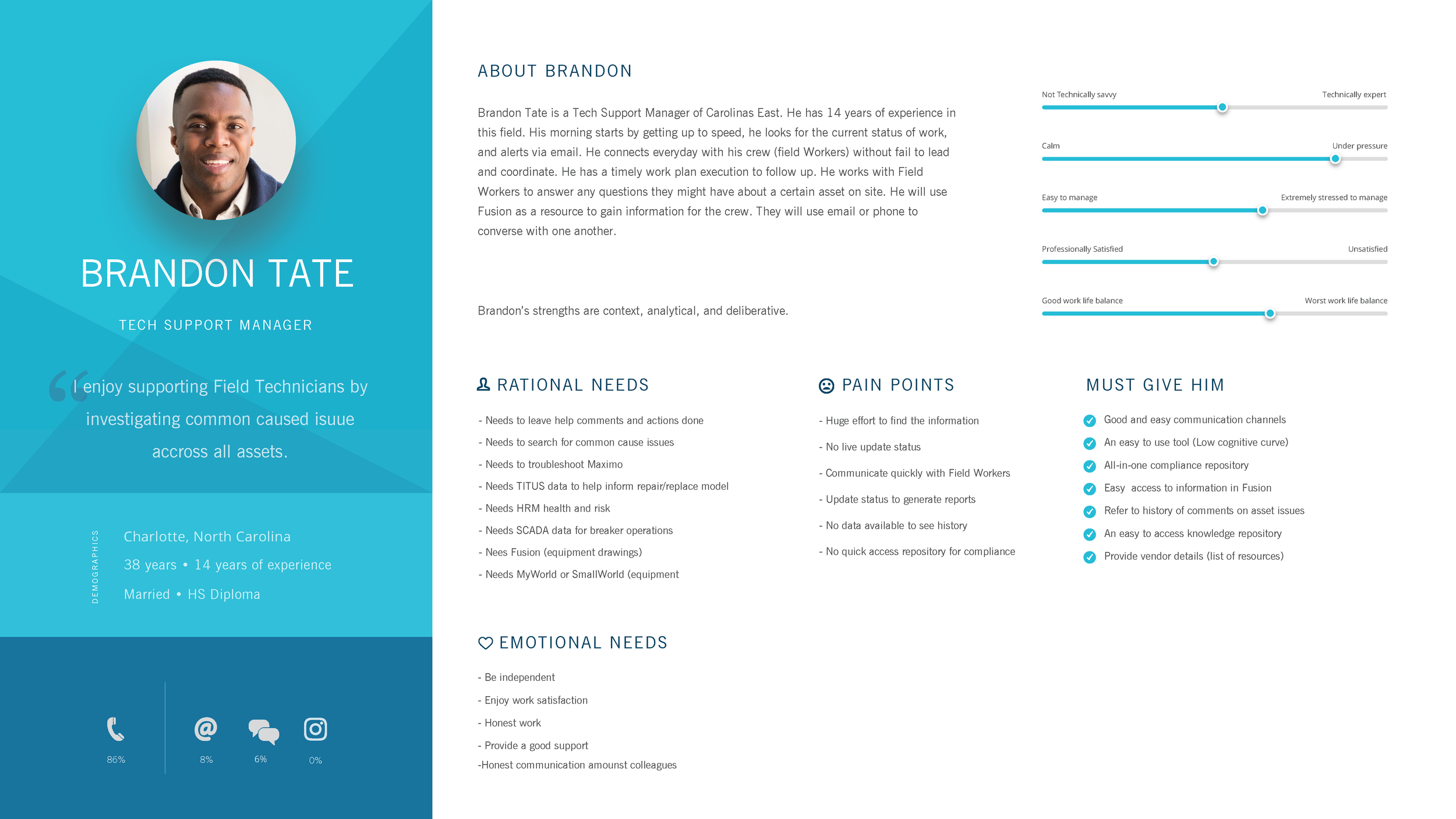

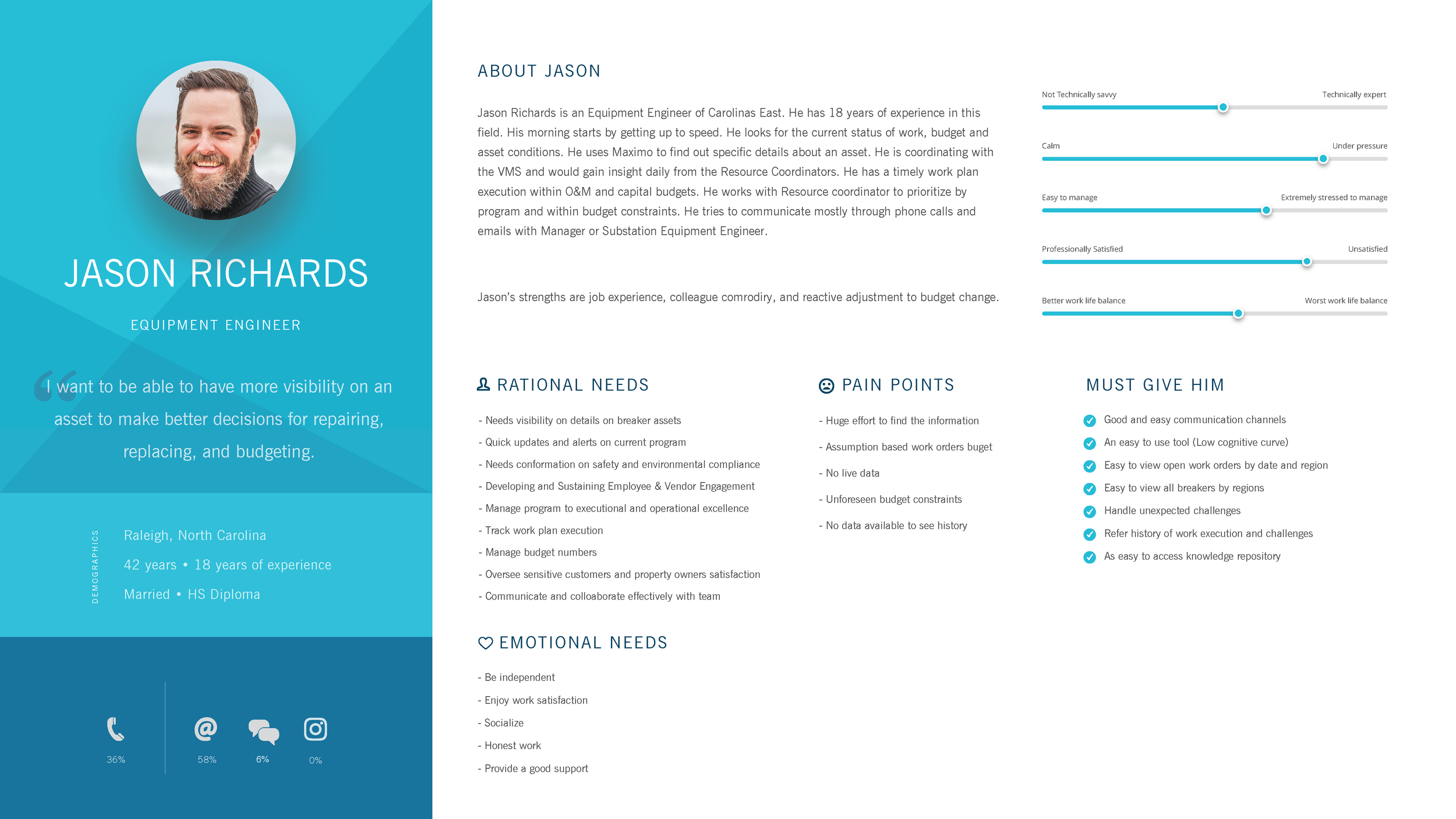

Equipment Engineering

-

Reliability Engineer

-

Technicians & Support

Paper Prototyping & User Testing

-

Equipment Engineering

“The application should recommend a starting point that I can validate”

-

Reliability Engineer

*No RE’s available

-

Technicians & Support

“I’ll only use it if it works. Nothing ever works right that you give me.”

User Testing

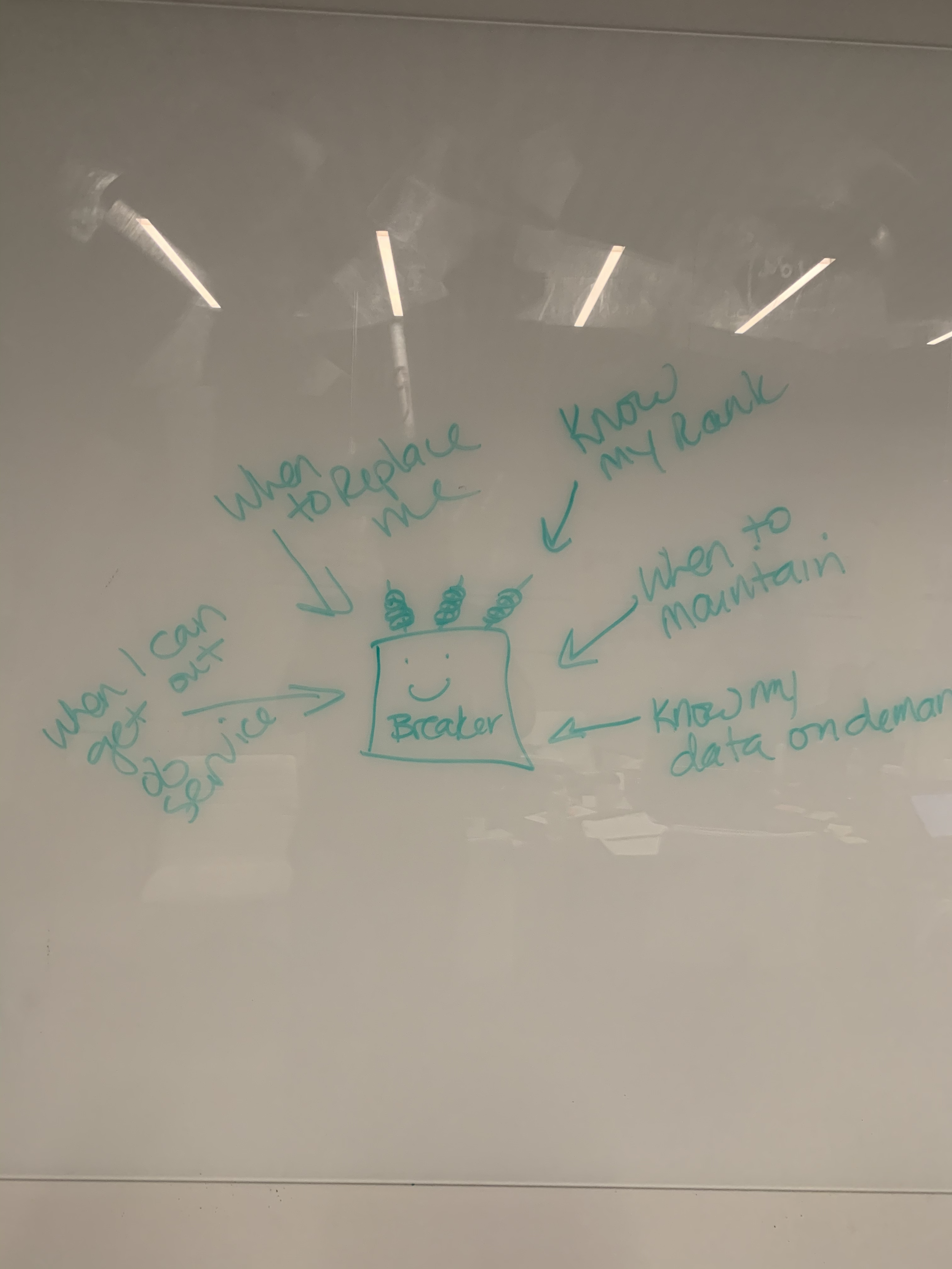

We tested a few employees within Transmission to get their thoughts as to how they could improve their workflow and workflow. Like their stakeholder counterparts, they wanted a centralized place where they could, see all equipment and its assets, the condition and manuals on that asset, and the next best approach for that asset. Here are a few below:

Prioritization Finals

-

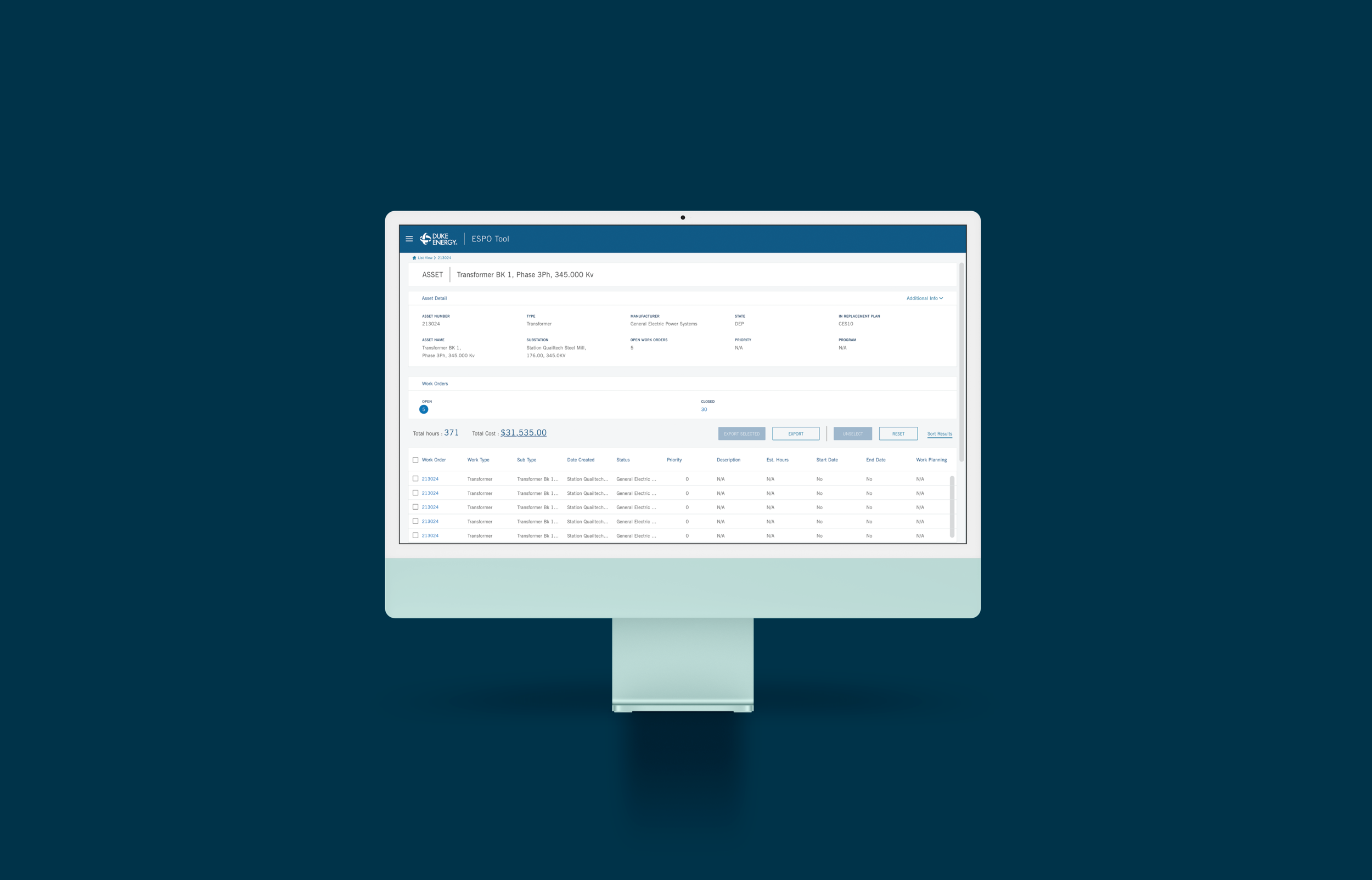

E.S.P.O Engineering & Maintenance

Why:

Desirable: High Adoption Estimate & Meets Needs

Feasible: Integrate into existing initiatives

Viable: Foundational for long term savings & risk planning

-

T.E.D.D Support & Technicians

Why Not:

Integrated into E.S.P.O

Aligned to Existing Initiatives

Fast Follow

-

Long Range Planning Reliability Engineers

Why Not:

Just Do It

Aligned to Existing Initiatives

Existing System Integration

Value Statement

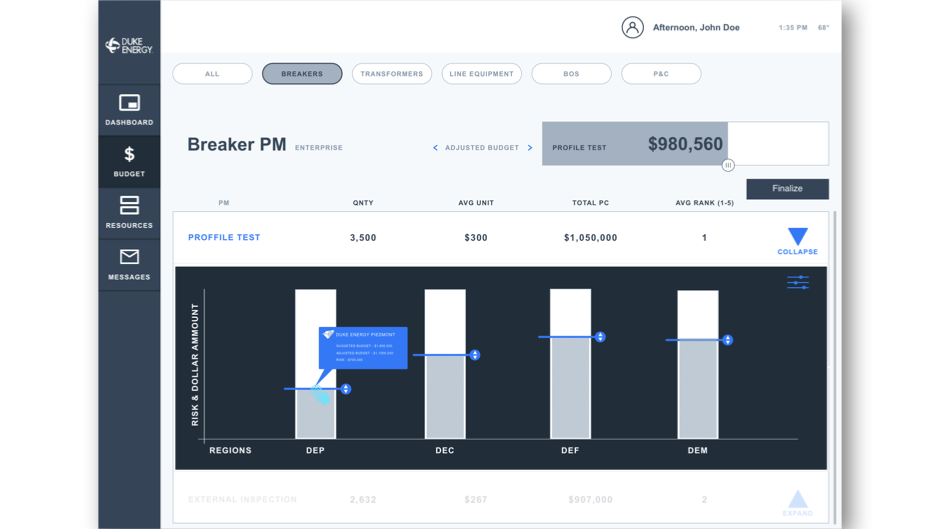

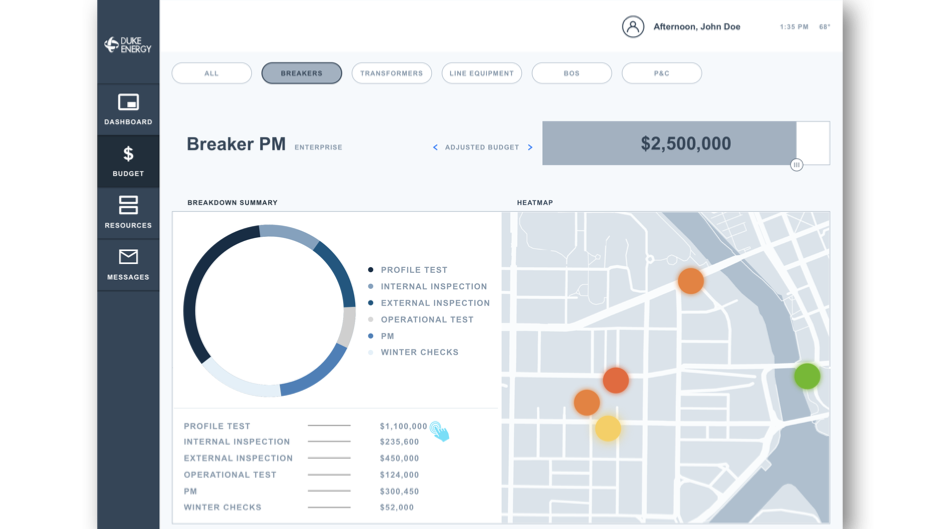

Equipment Strategy Planning & Optimization Tool will empower Equipment Engineering, Maintenance Support Technicians, and Reliability Program Engineers to make data driven replacement and maintenance decisions with 100% confidence.

This will be achieved by consolidating data from disparate systems to drive a combined maintenance and replacement strategy.

After Workshop : Refinery Phase

-

Equipment Engineering

What is the plan for this particular piece of equipment?

-

Reliability Engineer

What is prioritized to be worked on?

-

Technicians & Support

Should I replace or repair this piece of equipment?

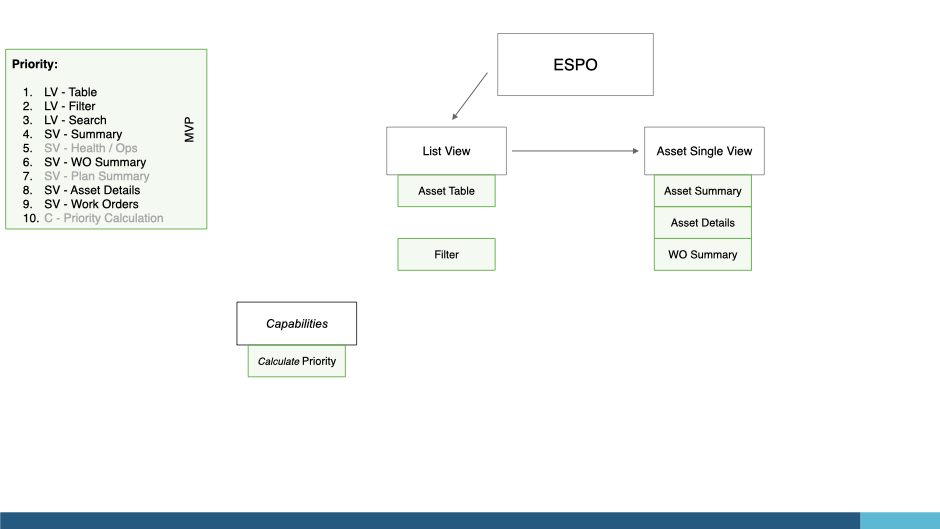

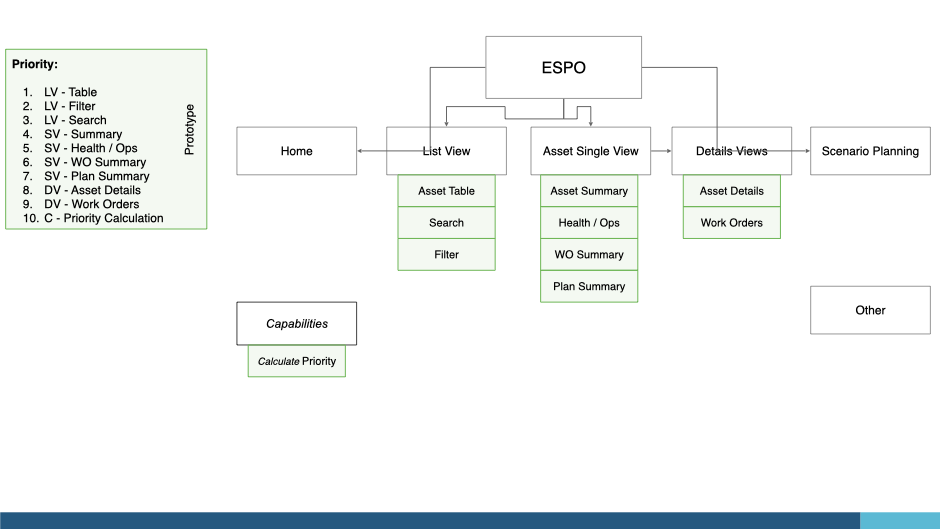

Sitemapping MVP

Process

The stakeholders and I were very pleased with the outcome of the ESPO tool. It served as a central hub where Transmission could have a list view of all assets and be able to drill down on it’s details; all on one application. The action to add comments and files could help the technical and field teams to interact with the app as well in a functional way. The workshop was so in depth and dynamic, it felt great to come to a point where the team was satisfied and couldn’t wait for an experience I help create, go into production. This tool should enable the completion of the highest priority work and facilitate the following outcomes:

20% reduction in unplanned spend

Expedited regulatory recovery in unplanned disruptions

25% reduction in maintenance work orders on end-of-life assets

Reduction in Customer Minute Interruptions (CMI)

Dynamic risk & cost plan

Conclusion

I really enjoyed being a creative and conceptual asset for this team. This was my first project in which I was a solo designer; enhancing my design and consulting skills in a multitude of ways. I was able to effectively listen and communicate to the stakeholders as we worked hand in hand for months. I was able to be fully immersed into the project, its full behaviors, and all its possibilities. For this project to be an “Exploration and Innovation” opportunity, it was a designer’s dream because there weren’t as many restriction; yet wanting to see how creative and user-centric we could be with our ideals.